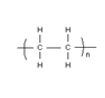

It is a thermoplastic used in a wide range of products It derives its name from the ethylene in form of monomer, polyethylene is manufactured by using ethylene. It is abbreviated name in the plastic industry is PE. The ethylene molecule C2H4 in fact consists of two CH2’s that are linked by a double bond. (CH2=CH2). Polyethylene is manufactured by polymerizing ethylene. The polymerization method can be radical polymerization, anionic polymerization, ion coordination polymerization or cationic polymerization. A different type of polyethylene is manufactured by each of these methods.

CLASSIFICATION OF POLYETHYLENE

Polyethylene is classified into various categories according to density and chemical properties. It depends on mechanical properties, molecular weight, crystal structure and branching type.

- UHMWPE (ultra high molecular weight PE)

- HDPE (high-density PE)

- HDXLPE (high-density cross-linked PE)

- PEX (cross-linked PE)

- MDPE (medium-density PE)

- LDPE (low-density PE)

- LLDPE (linear linked low-density PE)

- VLDPE (very low density PE)

PROPERTIES

Although its features vary according to type, its general properties include good resistance against external environmental conditions and humidity, flexibility, weak mechanical force and superior chemical resistance. It has a very wide area of use such as cans, plastic boxes, kitchen furniture, coatings, pipes and tubes, toys, isolation layers in cables, packaging and wrapping films, etc… Its cost is low.